Environmental Engineering Reference

In-Depth Information

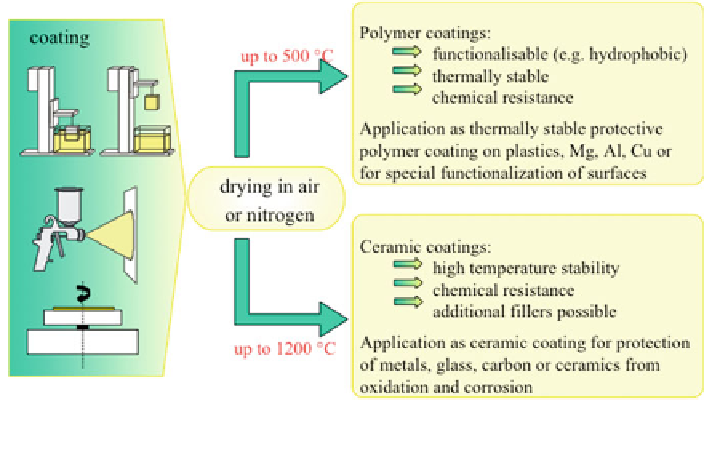

Fig. 7 Typical coating techniques involving preceramic polymers, as well as classification and

applications of the resulting coatings

The precursor technique thus exhibits a relatively low cost and easy approach to

produce polymeric and ceramic coatings. The coatings are mainly obtained from

silicon-based precursors such as polysiloxanes (Torrey and Bordia

2008b

), or

polysilazanes (G

nthner et al.

2009a

). In order to use preceramic polymers for

coating processes, either liquid state or solubility in organic solvents is necessary.

A tailorable rheology is a precondition for applying the suitable coating technology

to get the optimal coating performance.

ü

2.2.1 Polymer Coatings Based on Polysilazanes (T < 500

°

C)

In contrast to the limited thermal stability of coating systems based on organic

polymers, preceramic polymers have a higher temperature stability after they have

been cross-linked. In the case of the moisture-sensitive silazanes, this reactivity

leads to an additional cross-linking and is very advantageous for the adhesion of the

coating with the oxidic surface of the substrate due to reaction of functional groups

of the silazane precursor with

OH groups of, e.g., metals. Figure

8

shows a copper

sheet dip-coated with a silazane in the lower region and heat treated in air at 500

−

°

C.

Though the coating thickness is only 1

µ

m, the coating protects copper from

oxidation up to 500

C. In contrast, the uncoated region shows the typical oxidation

of copper into black copper oxides (G

°

nthner et al.

2007

).

Polysilazane can contain various functional reactive groups not only suitable for

cross-linking reactions. Functionalities of Si

ü

H, Si-vinyl, or N

H groups are pre-

-

-

destinated for further modi

cations due to their reactivity. Reactions with molecules

containing very polar groups such as carboxylates can lead to the modi

cation of

Search WWH ::

Custom Search