Environmental Engineering Reference

In-Depth Information

Table 9 Performance of engine-generator for power production

Test no.

Air

fl

ow

Solid fuel consumption

rate per a unit power

(kg/kWh)

Diesel replacement

rate (%)

Overall

ef

ciency

(%)

rate

(Nm

3

/h)

1

73.48

1.08

70.00

13.72

2

74.89

1.22

68.00

12.18

3

74.89

0.92

73.00

16.24

4

101.74

0.92

68.00

16.24

5

90.43

0.92

67.00

16.24

6

84.78

1.29

65.70

11.37

7

62.17

1.29

64.30

11.37

8

96.08

1.14

72.50

12.99

9

96.08

1.50

9.74

-

10

96.08

1.01

80.00

14.62

11

73.48

1.01

78.90

13.81

12

73.48

0.91

73.60

15.47

13

73.48

0.93

71.00

15.20

14

73.48

0.95

75.00

14.77

15

73.48

1.04

67.00

13.42

16

73.48

0.84

78.30

17.18

17

73.48

0.90

77.30

15.57

18

73.48

0.80

65.00

18.55

Max.

101.74

1.50

80.00

18.55

Min.

62.17

0.80

64.30

9.74

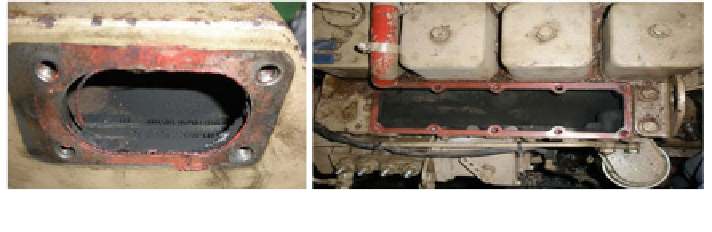

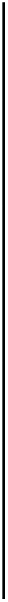

Fig. 6 Trap of soot at air cooler of the engine

4 Conclusion

Even 3Rs concept (Reduce, Reuse, and Recycle) is necessary for sustainable waste

management; however, the 4th R of Energy Recovery from waste must be taken

into consideration before

lling. Energy recovery from waste

is considered as green, clean, and renewable. Energy recovery from mined land

final disposal by land

ll

waste creates bene

t in term of land reclamation and reducing of fossil fuel used.

Search WWH ::

Custom Search