Environmental Engineering Reference

In-Depth Information

-

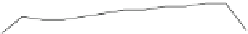

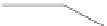

4

-3

-2

-1

0

1

2

3

4

-

4

-3

-2

-1

0

1

2

3

4

(a)

40

40

(b)

80

80

Diesel

VO

70-30 Diesel-VO

Biodiesel

30

30

60

60

20

20

40

40

Diesel

VO

70-30 Diesel-VO

Biodiesel

10

10

20

20

0

0

0

0

-4

-3

-2

-1

0

1

2

3

4

-4

-3

-2

-1

0

1

2

3

4

Radial Distance (cm)

Radial Distance (cm)

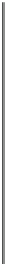

-

4

-3

-2

-1

0

1

2

3

4

-

4

-3

-2

-1

0

1

2

3

4

20

20

25

25

(c)

(d)

20

20

Diesel

VO

70-30 Diesel-VO

Biodiesel

15

15

15

15

10

10

10

Diesel

VO

70-30 Diesel-VO

Biodiesel

10

5

5

5

5

0

0

0

-4

-3

-2

-1

0

1

2

3

4

-4

-3

-2

-1

0

1

2

3

4

0

Radial Distance (cm)

Radial Distance (cm)

Fig. 14 Radial pro

les of CO and NO

X

concentrations (a, b) 10 % AA, (c, d)15%AA

temperature, resulting in poor thermal feedback from the flame to prevaporize the

fuel droplets. Several options were considered to increase the

fl

fluid temperature in

the near

field of the spray: exhaust gas recirculation, preheated combustion air, and

vitiated combustion air. However, a simpler solution was to combine glycerol

combustion with methane combustion. The methane

flame around the glycerol

spray provided thermal feedback to prevaporize glycerol droplets and to help

preheat the resulting fuel

fl

air mixture to the required ignition temperature. The

methane combustion also increased the overall reaction rates and helped ensure

suf

-

cient residence time to oxidize the decomposed species produced during

glycerol combustion (Simmons et al.

2010

).

In this section, the range of stable operating conditions and resulting emissions

of glycerol

flames in a swirl-stabilized combustor operated at atmospheric

pressure are reported. These results have subsequently been used to re

methane

fl

-

ne the

burner concept to achieve even greater fuel

flexibility while minimizing the envi-

ronmental impact (Jiang and Agrawal

2014

; Jiang et al.

2014

). First, the heat release

fl

Search WWH ::

Custom Search