Environmental Engineering Reference

In-Depth Information

of either kinetic energy or potential energy, as discussed in Sect.

3

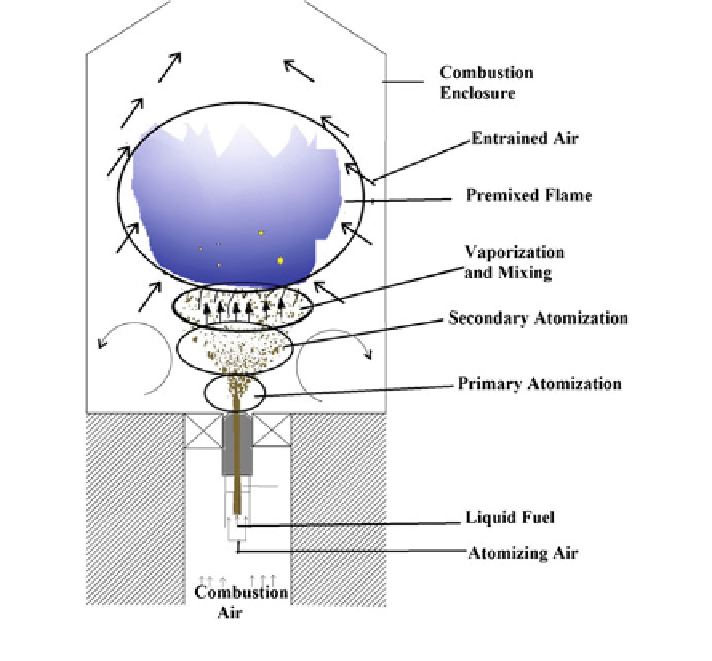

. The atomization

process generally takes place in two steps: during primary atomization, the fuel is

broken into ligaments and blobs at the injector exit. Subsequently, ligaments and

blobs interact with the atomizing air and/or combustion air to undergo secondary

atomization resulting in a fuel spray containing droplets of a wide range of

diameters.

Droplets in the spray vaporize and premix with air, depending upon the

ow,

thermal, and chemical processes. Fuel vaporization depends upon parameters such

as the boiling and/or fuel volatility characteristics, latent heat of vaporization, and

initial droplet diameter. Clean combustion requires appropriate fuel droplet size

distribution, for a range of operating conditions, such that the droplets are both large

enough to penetrate into the combustion chamber, but also small enough to prev-

aporize within the short residence time of the spray/

fl

fl

ame region. If they can be

ignited, large droplets in a spray burn in the diffusion

flame mode, which results in

unacceptably high emissions of NO

X

, carbon monoxide (CO), soot, and unburned

hydrocarbons (UHCs). The LDI combustion concept in Fig.

1

illustrates excellent

fuel prevaporization and fuel

fl

-

air premixing. The fuel and air

fl

ow rates are

Fig. 1 Illustration of lean direct injection (LDI) combustion

Search WWH ::

Custom Search