Environmental Engineering Reference

In-Depth Information

initially on the left side only, spread all around the base of the

flame. This was

accompanied with subsequent reduction in the yellowish component and an

increase in the bluish component of the

fl

fl

ame. The

fl

flame height also kept on

reducing slightly. Another characteristic feature of the

fl

flame noticed was that of the

fl

flame being present more on one side of the burner than the other, due to swirling.

This is because the swirl is directional, and it makes the air to move in a particular

direction (anticlockwise), and hence the

fl

flame also has some of these directional

characteristics.

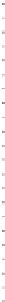

Figure

6

represents the variation of temperatures normalized with the tempera-

ture of the corresponding diffusion

ame. It can be observed that the temperature

decreases only slightly initially as the premixing air is introduced and increased.

After that there is a steep reduction in temperature. The temperature rises from

Φ

p = 3.32, till

fl

Φ

p = 2.77, then reduces slightly at

Φ

p = 2.38, and then again rises to

a higher temperature at

Φ

p = 1.85. With further addition of premixing air, the

temperature falls to its minimum at

Φ

p = 1.11. The data presented in Fig.

6

show

that the temperature for partially premixed

flame is lesser than the temperature

observed for the corresponding pure diffusion

fl

flames. This can be attributed to

cooling due to premixing air addition and counters the premise of improvement in

combustion in the presence of increased premixing air. At higher primary air

fl

fl

ow

Φ

p), the swirling ef

rates (lower

ciency of air increases causing better and thorough

mixing of fuel and air resulting in an increase in temperature rather than just

increasing the air velocity and causing cooling effect.

Figures

7

and

8

present the variation in CO and UHC concentrations with

premixing equivalence ratio. It shows that CO and UHC concentration increases

from that for a purely diffusion

fl

flame with increasing levels of premixing and peaks

at

Φ

p = 3.32. Figure

6

had shown that the exit temperature decreases in this range

and this decrease is especially sharp around this point. As the combustion is hin-

dered due to the decrease in temperature, which in turn is caused by the presence of

an excess of primary air, the concentration of CO increases. However, the

fl

ame

Fig. 6 Temperature variation

with premixing equivalence

ratio

1.00

Normalized Temperature

0.98

0.96

0.94

0.92

0.90

0.88

0.86

0.84

0.82

0.80

0

1

2

3

4

5

6

7

8

9

10 11 12

Φ

p

Search WWH ::

Custom Search