Environmental Engineering Reference

In-Depth Information

been measured at a central location in the combustor, for certain sets of prede

ned

conditions. The corresponding

flame heights have also been analysed and compared

at these conditions. Based on the available data, an optimal level of premixing has

also decided upon in this study.

fl

2 Experimental Setup and Procedure

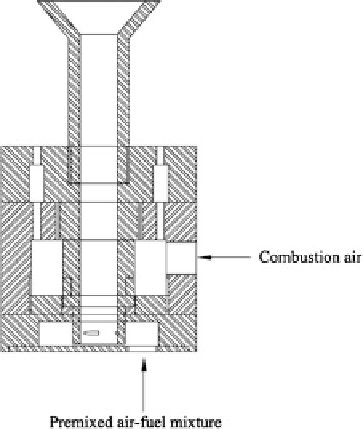

The schematic diagrams of the burner con

guration and the experimental setup

have been shown in Figs.

1

and

2

, and a picture of the burner is shown in Fig.

3

.

The primary (premixing) and the secondary (diffusion) air are both taken from a

storage tank connected to an air compressor through separate lines. Both the air

ow

rates are measured using a rotameter each. The fuel is taken from a domestic LPG

tank and its

fl

flow rate is also measured using a rotameter. A pressure gauge is

provided to read the gauge pressure at the inlet of each rotameter. It is assumed that

there is no drop in the pressure across any of the rotameters, as the inlet valve is

completely opened for all the measurements. The

fl

flow rate is controlled using a

needle valve, one provided at the exit of each rotameter.

The premixing air and the fuel pass through the respective rotameters into a

premixing chamber, where they are thoroughly mixed. And from there, this pre-

mixed mixture is supplied to the burner. This premixed mixture comes out through

the centre of a

fl

fixed in

the centre of a perforated plate in the burner. There is a provision for tangential

swirling, through tangential slots cut at right angles at the bottom of the burner. The

premixed fuel

fl

flame holder, having diameter of the central tube as 10 mm;

air mixture enters the bottom of the burner, swirls through these

-

Fig. 1 Schematic of the

burner used in the experiment

Search WWH ::

Custom Search