Environmental Engineering Reference

In-Depth Information

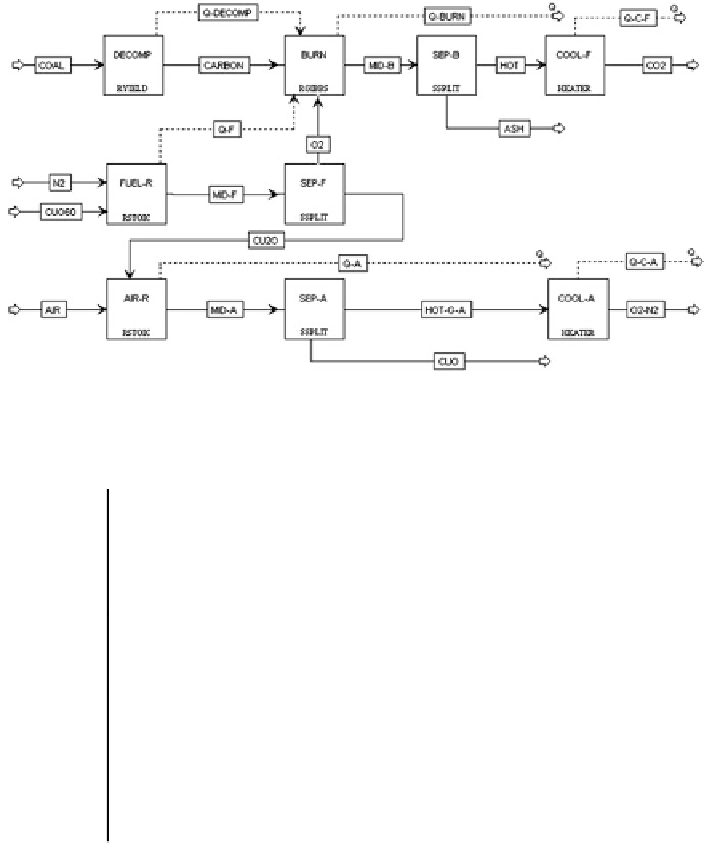

understanding the reaction equilibrium behavior. For Abad et al.

s experimental

setup (

2012

), we established an ASPEN Plus model as shown in Fig.

4

.

As summarized in Table

5

, coal devolatilization is de

'

ned by the RYIELD

reactor, followed by the gasi

cation of coal represented by the RGIBBS reactor.

The RSTOIC reactor de

nes the actual fuel combustion. It should be noted here that

these three reactor blocks together in Fig.

4

represent the fuel reactor in Abad

et al.

flow sheet within the ASPEN Plus simulation

package cannot model this entire reaction with one reactor. As a result, the fuel

reactor is broken down into several different reactor simulations. The air reactor is

modeled as an RSTOIC reactor. The molar

'

s experiments (

2012

). The

fl

fl

flow rate of CuO exiting and Cu

2

O

Fig. 4 Overall

fl

flow sheet of CLOU process in ASPEN Plus

Table 5 Process models used in different parts of CLOU process in ASPEN Plus

Name

Model

Function

Reaction formula

DECOMP

RYIELD

Coal devolatilization and

gasi

cation

Coal

→

volatile matter + char

BURN

RGIBBS

Syngas and char burn with

O

2

Char + volatile

matter + O

2

CO

2

+H

2

O

→

FUEL-R

RSTOIC

Carrier reduction reaction

4CuO

2Cu

2

O+O

2

→

AIR-R

RSTOIC

Carrier oxidation reaction

2Cu

2

O+O

2

→

4CuO

SEP-F

SSPLIT

O

2

and Cu

2

O Separation

*

SEP-A

SSPLIT

CuO and air Separation

*

SEP-B

SSPLIT

Separation

—

ash and

fl

ue

*

gas

COOL-F

HEATER

Flue gas cooler

—

fuel

reactor

H

2

O (gas)

→

H

2

O (liquid)

COOL-A

HEATER

Flue gas cooler

—

air reactor

*

Search WWH ::

Custom Search