Environmental Engineering Reference

In-Depth Information

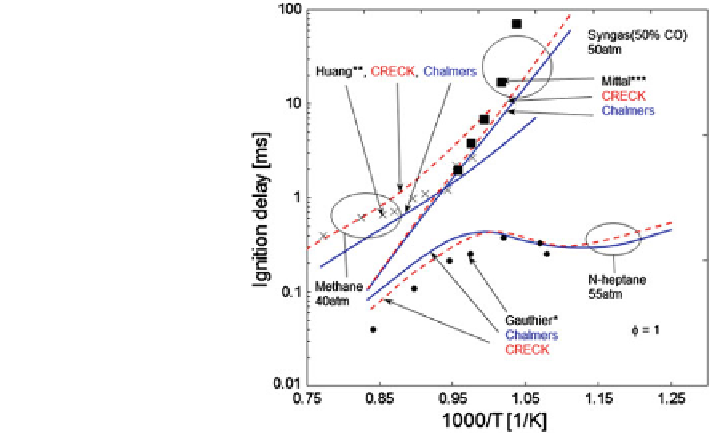

Fig. 9 Predicted and

measured ignition delays for

n-heptane/air, syngas/air, and

methane-air mixtures at high

pressures and

ϕ

=1

experiments, but were not duplicated in simulations (Dryer and Chaos

2008

; Jain

et al.

2013

). It is also noteworthy that the Chambers mechanism is able to reproduce

the experimentally observed two-stage ignition process and negative temperature

coef

cient (NTC) region.

4.2 Ignition Characteristics in Dual-Fuel Diesel Engines

In a dual-fuel engine, the ignition is initiated by the pilot diesel. Since ignition

represents a critical process with regard to engine performance and emissions, it is

important to examine the ignition of pilot fuel in the presence of a combustible

gaseous fuel-air mixture. In particular, the ignition chemistry of large hydrocarbons,

such as n-heptane, is known to be characterized by the NTC (negative temperature

coef

cient) and two-stage ignition processes (Curran et al.

1998

). Previous studies

have not analyzed the effect of gaseous fuels on these processes. Therefore, sim-

ulations were performed to examine these aspects by considering homogeneous

gaseous mixtures in a constant volume reactor and two-phase mixtures in a diesel

engine. Figure

10

depicts the

first and second stage ignition processes in diesel

engine in terms of the mass pro

les of OH and QOOH with respect to crank angle

for the single- and dual-fuel cases, as listed in Table

3

. As indicated in the table, the

start of injection (SOI) is

after top dead center (ATDC), and injection duration

is 8.5 crank angle degree (CAD).

For n-heptane, the two-stage ignition process is well depicted in the

−

8

°

figure, with

the

first-stage ignition occurring at

−

4.8

°

ATDC and the second-stage at

−

2.4

°

ATDC. The

first-stage ignition is de

ned by the value of integrated heat release

Search WWH ::

Custom Search