Environmental Engineering Reference

In-Depth Information

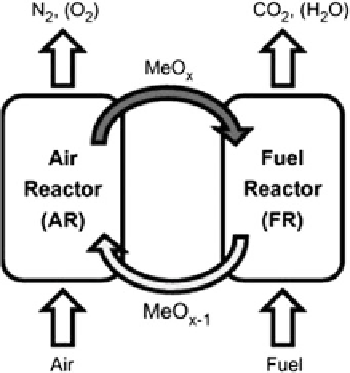

Fig. 7 The concept of

chemical-looping combustion

(CLC) is based on the

application of fluidized bed

technology (Penthor et al.

2014

)

5 Conclusions

It can be seen that the

fluidized bed technology is a very useful technology which

has been applied in a wide range of power generation applications. Fuels as dif-

ferent as coals, biomass, sludges, and waste with different qualities can be utilized

well in

fl

fluidized beds.

Scale-up has been continued and recently successfully demonstrated in the 600

MWe size range. High ef

fl

ciencies can be achieved using supercritical and ultra-

supercritical steam conditions in large-scale CFB boilers. Those units are based on

coal.

Biomass is utilized using

fl

fluidized bed technology as well. Biomass can be

added to large-scale

fluidized bed boilers; however, biomass is typically utilized in

smaller scale. Those biomass combustors operate usually in a size range from about

30 to about 130 MWth. On the other hand, there are a few large-scale biomass-

based FBC in operation. The world

fl

is largest at present is the Polaniec CFB boiler in

Poland with a capacity of 447 MWth.

The

'

fluidized bed technology is very suitable to utilize wastes, for example,

assorted MSW, RDF, and even plastics. Typically, the FBCs are in a smaller size

range, which extend from 40 to 140 MWth, similar to those FBCs which are based

on biomass utilization.

Novel concepts and successful demonstrations using

fl

fluidized bed technology

are already on the market or under development, for example, the steam gasi

fl

cation

of biomass wherein the syngas produced is rich in H

2

and CO which can be used for

synthesis or in gas engines or oxyfuel combustion which produces a CO

2

-rich

fl

ue

gas which signi

cantly helps in CO

2

removal or in chemical-looping combustion

(CLC).

Search WWH ::

Custom Search