Environmental Engineering Reference

In-Depth Information

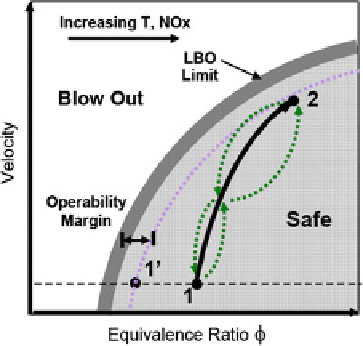

Fig. 1 Detailed schematic of combustor operating regime and transients. The operating regime

(solid line) is designed such that the worst possible state (2) lies with safe margin from LBO limit.

As a result, the other operating states (such as 1) become non-optimal state produce more NO

x

(Chaudhari

2011

)

Thus, presently, the scheme of avoiding LBO by operating the combustor in rich

condition regime with a wide margin above the LBO limit tends to increase the NO

x

formation from engine. Enhanced performance can therefore be obtained with a

reduction in this margin. So, the ability to sense the proximity of combustor to

incipient LBO can provide signi

cant payoff in terms of operation economy and

reduce the overall emission.

1.1 Flame Dynamics Toward Lean Blowout

Before LBO, the

fl

flame shows some large-scale unsteadiness. Many studies char-

acterize this

fl

flame behavior toward LBO. Nicholson and Field (

1949

) reported that

the

flame undergoes large-scale pulsation as the combustor approaches blowout.

They also observed the repeated detachment and reattachment of

fl

fl

ame to the

fl

ame

holder before extinction. Hertzberg et al. (

1991

) reported similar pulsation of

ame.

Increased ignition time and local extinction of flame due to high instantaneous

strain rate are considered as the major causes of blowout. Chao et al. (

2000

)

observed the jet

fl

fl

flame for characterizing the blowout dynamics. They observed the

fl

flame blowout transience turning off the acoustic excitation. They postulate that the

blowout transient process can be divided into four regions: the pulsating, onset of

receding, receding and extinction. They found the

flame base pulsate in pulsating

region before the onset of liftoff and eventually blowout. Through LIPF and PIV,

they found that high strain rate encountered by the

fl

flame base which is more than

extinction strain rate is the primary cause of blowout process. Hedman et al. (

2002

),

fl

Search WWH ::

Custom Search