Environmental Engineering Reference

In-Depth Information

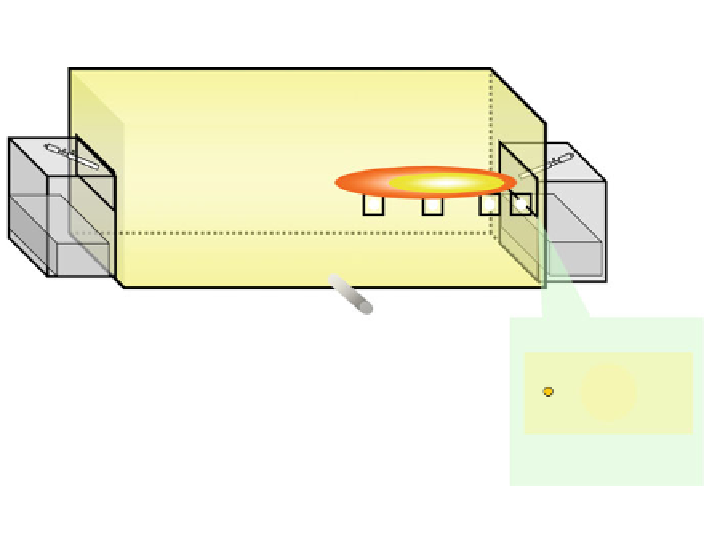

Thermal couples:(3

×

8)

8.0 m

2.0 m

2.0 m

Window

D

Window

C

Window

B

Window

A

Burner: A

Burner B

Exhaust duct

Fuel injector for

premixed combustion

Nitrous Oxide Analyzer

Air injector

Fuel injector for

diffusion combustion

Fig. 1 Schematic diagram of regenerative test furnace for steel slub preheating. Fuel: heavy oils

or natural gas

filters, merged again in the view

field of the video camera through another half mirror

after re

fl

ected. Either mirror was slightly tilted to separate the two-color images in the

view

field. Each pixel data obtained from the video camera was processed to obtain

temperature by post-numerical processing based on Eqs. (

1

) and (

2

).

3 Result and Discussion

Figures

3

and

4

show the one-shot pro

les of soot temperature observed through the

window A (upstream) and B (middle stream) during the premixedand diffusion

combustions, respectively.

It is clearly demonstrated in the

figure that during the premixed combustion the

high-temperature zone (shown in white) is observed around the left edge of

the window A. This high-temperature zone was found to be very steady, leading to

the high level of NO

x

emission over 120 ppm. Near the injector, premixed gas

undergoes very fast combustion reaction, leading to the high-temperature zone,

leading to high NO

x

emission.

On the other hand, the high-temperature zone is not encountered in the upstream,

during the diffusion combustion. It was found from a series of pro

le data that the

Search WWH ::

Custom Search