Environmental Engineering Reference

In-Depth Information

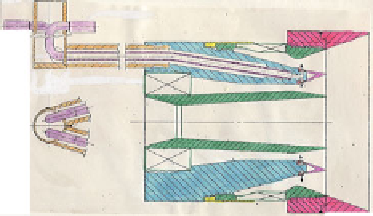

Radial

swirler

D=4”

Moderate swirl

Configuration 1/2

Weak Swirl

Configuration

3

Fuel nozzle with 3 swirlers ranging from weak

to moderate swirl strength; single or twin

rows of fuel jets in swirling cross streams.

Axial

swirler

Fig. 50 LDI-based combustor cross-section from Mongia (

2011b

)

swirlers) were tried; radial in

ow swirler closer to exit plane of the premixing tube

gave the best results. Typical air

fl

ow distribution at the simulated max-max power

(T

3

= 1158 K and P

3

= 490 kPa) is given in Fig.

51

along with its CO and NO

x

EI

characteristics in Fig.

52

. Two interesting observations need to be made here. First,

its NO

x

/P

0.5

value ranges between 0.6 and 1.5 EI/atm

0.5

which is very competitive

with the lowest values discussed earlier concerning Figs.

37

and

44

. Second, the

mixer survived during extensive rig testing at temperatures exceeding 1328 K with

the corresponding ignition delay times less than 0.2 ms even when the mixer may

be classi

fl

ed as a premixing and not LDI which we do not agree for the reasons

outlined in the following paragraph.

First, we used liquid fuel injection at the throat of two concentric venturis

involving both radially inward and outward directions normal to cross swirling

fl

flows, JIC. Second, two separate diverging concentric passages followed axially

downstream of JIC. This was followed by continuous fuel/air mixing in a single

diverging passage until the radial swirler. The swirl strength of the three concentric

swirlers was optimized, which starting from center increased from very weak

(

) for the outer-mounted

injector swirler, as shown in Figs.

49

and

50

. The point of disagreement could be

≤

15

°

),

to weak (

≤

30

°

), and moderately strong (

≤

45

°

Fig. 51 Air

fl

flow distribution of the mixer configuration tested at

the simulated max-max

operating point; from Mongia (

2011b

)

Search WWH ::

Custom Search