Environmental Engineering Reference

In-Depth Information

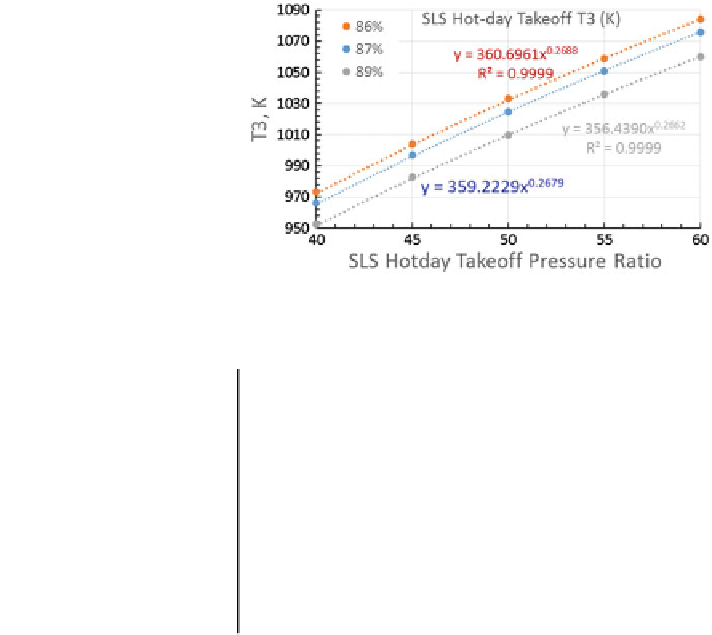

Fig. 20 SLS hot-day takeoff

combustor inlet temperature

versus ICAO takeoff pressure

ratio for different isentropic

efficiencies

Table 5 Academic ignition delay times (ms) for 45 and 60 takeoff pressure ratio from Sung

(

2014

)

SLS takeoff pressure ratio

45

60

ICAO T3*, K

902.6

889.6

974.8

960.4

˄

ign

(for 0.7

˕

), ms

1.82

1.83

1.02

0.82

˄

ign

(for l.0

˕

), ms

1.19

1.19

0.73

0.76

Det. Hot-day** T

3

, K

1004.0

989.9

1084.0

1068

˄

ign

(for 0.7

˕

), ms

1.08

1.27

0.34

0.41

˄

ign

(for l.0

˕

), ms

0.83

0.98

0.27

0.32

*

ʷ

isen

, %

87

89

87

89

**

ʷ

isen

, %

86

88

86

88

damage. The minimum

˄

ign

of 0.83 ms for the hot-day, fully deteriorated engine at

stoichiometric condition can therefore be considered safe for this engine. If one

moves forward with an N + 1 generation 60 OPR engine, then the calculated

˄

ign

goes down by a factor of 3

0.27 ms with potential for requiring changes in the

combustor design in order to address F

-

3

concerns, if any. However, there will be

some increase in

˄

ign

to 0.32 ms for the N + 2 generation engine.

2.6 Operability Challenges

Combustion system is a unique part of the gas turbines in that its design require-

ments have to be met from engine start to the most severe operating conditions

including the highest engine pressure and temperature levels, as discussed in the

previous section. There are several demanding requirements beyond low-emissions

including durability, shop visits, and combustor exit temperature quality that rarely

get the attention of the people beyond the combustion design community. An

aviation engine must perform reliably over its

fl

flight envelope. The theoretical

Search WWH ::

Custom Search