Environmental Engineering Reference

In-Depth Information

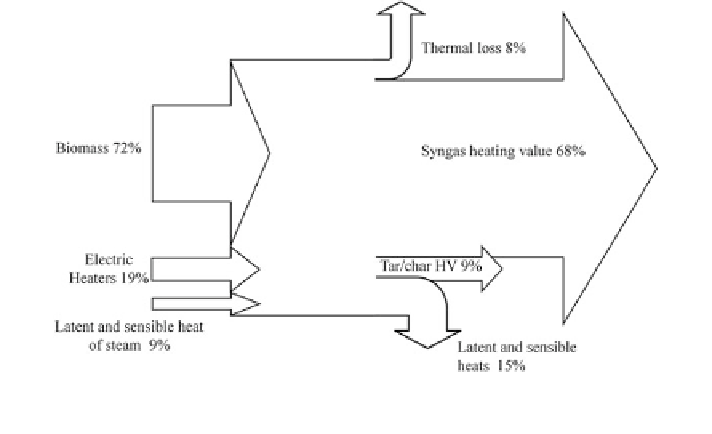

Fig. 13 Energy

fl

flow diagram for maximum energy efficiency case. (T = 857

°

C, S/B = 0.75,

= 2.4 s)

τ

of the syngas. As shown in the previous section, the heating value of the syngas

decreased as the reactor temperatures rose, but the total heating content (heating

value x

flow rate) increased. An increase in temperature would most likely increase

the conversion ef

fl

ciency further. Adding a heat exchanger could also increase the

energy ef

ciency. Recovery of any of the sensible heats of the steam or syngas

mixture would reduce the required energy input and increase energy ef

ciency.

ciency case is shown in

Fig.

13

. The biomass heating value accounted for 72 % of the energy input, while

19 % was required to heat the reactor bed and 9 % for the generation of steam. The

total process energy converted to chemical potential in the syngas was 68 %.

Reactor thermal losses consumed 8 % of the input energy. This portion can be

reduced by better insulating the reactor. The thermal loss during this test was

7.8 kW. Lower thermal losses were accomplished after this particular test with

better insulation wrapping. The results presented here are using the measured losses

to accurately portray testing.

The Latent and sensible heat contained by the steam and syngas accounted for

15 % of the total energy. This energy is available to be recycled back into the system

using heat exchangers. Because of the higher tar content produced at low S/B ratios,

some form of tar treatment will be needed to prevent reduction in heat exchanger

ef

A heat

fl

flow diagram for the maximum energy ef

ciency. The easiest way to prevent tar buildup in a heat exchanger is only cool

the syngas mixture down to 400

C. In this way, most of the tars are prevented

from condensing. While effective, this method will limit the amount of recoverable

heat. Another option is to use a catalytic tar reformer. This heated vessel will remove

most of the tars and thus allow the gas to pass through a heat exchanger that can

utilize the full energy potential of the heated gas. Although this adds infrastructure

and energy cost to maintain another bed at high gasi

°

cation temperatures.

Search WWH ::

Custom Search