Environmental Engineering Reference

In-Depth Information

increased CGE with increased temperature holds for all of the facilities. The CGE

found in the present study matches (within limits of error) the results obtained by

Franco et al. at temperature above 750

°

C. The agreement in the CGE values

con

rms proper operation of the gasi

er energy measurement systems.

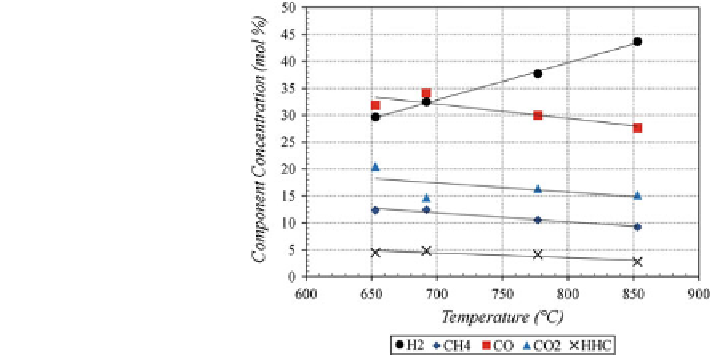

3.1 Syngas Composition

The effect of the reactor temperature on syngas composition was studied between

650 and 850

C. Figure

7

shows the concentration of the major syngas constituents

for moderate S/B ratios and residence times. At 650

°

C, carbon monoxide was the

most dominant syngas component at 32 mol%, followed closely by hydrogen at

30 mol%. When the reactor temperature was raised, the hydrogen concentration

increased, while all of the other constituents gradually decreased. At 775

°

C,

hydrogen was the most dominant species at 38 mol% and carbon monoxide levels

had dropped to 30 mol%. This trend continued when the reactor temperature was

raised to 850

°

C, where a hydrogen concentration of 44 mol% was recorded. Part of

the reason for the increase in hydrogen concentration was the cracking of hydro-

carbons. Methane levels dropped from 13 to 10 mol%, and higher hydrocarbon

(HHC) levels dropped from 5 to 3 mol%.

The effect of temperature on HHC concentration is shown in Fig.

8

. Ethylene

(C

2

H

4

) levels increased as the reactor temperature was raised from 650 to 775

°

°

C

before falling to its lowest level at 850

C. The increase in ethylene concentration

could have been from the cracking of propylene (C

3

H

6

). Propylene contains two

carbon atoms joined by a double bond (like ethylene) and with a methyl (methane)

group attached to it. All of the other HHCs decreased in concentration with each

subsequent increase in temperature. The resulting sum of the HHC

°

'

s decreased with

Fig. 7 Effect of temperature

on gas composition (S/

B = 2.0

±

0.1,

τ

= 2.0

±

0.4 s)

Search WWH ::

Custom Search