Biomedical Engineering Reference

In-Depth Information

(b)

100%

50%

0%

0 00

200

300

(a)

(c)

500 nm

Diameter/nm

100.00

10.00

1.00

0.10

0.01

(d)

Wt% H

2

O

100

Wt% coating

Nb% H

2

O

Nb% coating

50

0

1

10

100

Diameter/nm

1000

10000

(e)

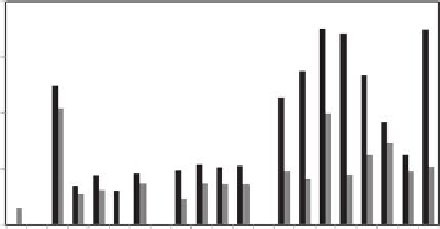

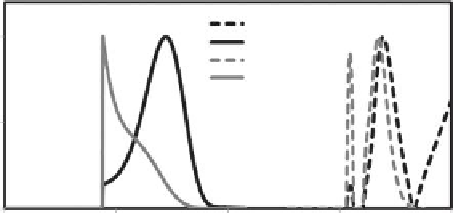

FIGURE 3.2

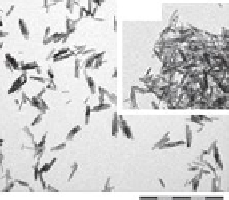

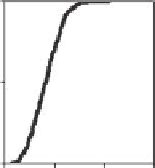

Classification results from multiple labs and several methods on an identi-

cal batch of iron oxide hydrate Pigment Yellow 42. (a) Monolayer-transmission electron

microscopy (TEM) images after dipping the grid in the sample that was wetted by ethanol;

(b) another sector on the same grid, which had to be excluded from evaluation; (c) TEM size

distribution resulting from semiautomated evaluation of 282 primary particles; (d) median

diameter in the originally measured metrics (black) and after conversion to number metrics

(grey). (Replotted from Gilliland D, Hempelmann U (2013) Inter-laboratory comparison of

particle size distribution measurements applied to industrial pigments and fillers. Presented to

ECHA (European Chemicals Agency), October 2, 2013.) The values of TEM-BASF originate

from plot (c), and the values of CLS-BASF originate from plot (e) dashed lines; (e) full size

distributions from centrifugal liquid sedimentation (CLS) in mass metrics (black) converted

to number metrics (grey), with powder dispersed by probe sonication in H

2

O with a dispersant

(dashed lines) or dispersed by application-specific shaking in organic coating (solid lines).

Search WWH ::

Custom Search