Biomedical Engineering Reference

In-Depth Information

Machining by sanding,

band-saw, abrasion,

rotary cutting wheel, wet

saw cutting, wet drilling,

grinding. (moderate

temperature + moderate

to strong mechanical

stresses: energy input

per test by sanding

estimated is 10-fold

higher than by sawing)

(LeBihan et al. 2013)

No standard simulation

machines: monitoring by

APS, CPC, SMPS, ESP,

FMPS, LDPSA, NSAM,

OPC, and sampling for

characterization by SEM/

TEM, EDX, AUC, LD,

XPS

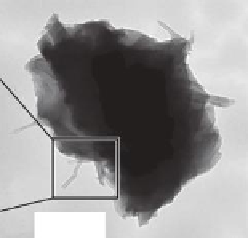

Fragments from CNT-epoxy

were submicrons in diameter

and carried protrusions of

CNTs that were pulled out

from the matrix (Cena and

Peters 2011)

Many laboratory studies on

different CNT-polymer and

nanoparticle-polymer

composites found no release of

free nanoillers (Cena and

Peters 2011; Fleury et al. 2013;

Göhler et al. 2010, 2013; Hirth

et al. 2013; Koponen et al.

2010; Wohlleben et al. 2011,

2013) with exceptions linked to

agglomerates in the polymer

(Golanski et al. 2012; Huang

et al. 2012)

300 nm

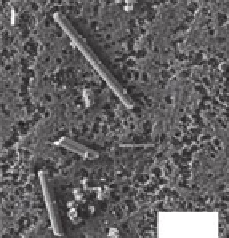

Fragments from CNT-

polyoxymethylene measured

microns in diameter with no

protrusions (Wohlleben et al.

2011)

Protrusions of CNTs were not

observed for tough

thermoplastics (Wohlleben

et al. 2011, 2013) which can

elongate during machining and

keep CNTs embedded (Hirth

et al. 2013; Schlagenhauf et al.

2012)

59.78

µ

m

19.74

µ

m

4.97

µ

m

20

µ

m

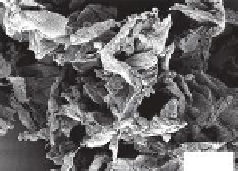

Machining by dry drilling

or milling (moderate

mechanical stress at

elevated temperatures)

No standard simulation

machines. Detect aerosols

around machines by APS,

CPC, Dust TrakTM, ESP,

FMPS, TP, TSI

Polymorph aerosol sampled

during dry drilling of a

graphite-epoxy pre-preg

with aligned carbon ibers

and aligned CNTs (Bello

et al. 2010)

By synergy of degradation and

stress, machining with local

overheating is a key release

scenario

20

µ

m

(

Continued

)

Search WWH ::

Custom Search