Biomedical Engineering Reference

In-Depth Information

12.2.8 m

eChaniCal

s

hoCk

Mechanical shock is another special case of low energy mechanical processes. This

process is seen to simulate short hits as they may occur when the product falls down

to the ground or experiences sudden mechanical hits by accident. This process can

be simulated by a vibrating plate engraver with a round tip as was used by Golanski

et al. (2012). Release of CNTs from the matrix is reported by Golanski et al. (2012)

using the engraver but no further details on the method and CNT identification are

given.

Another method employed is the one used by Le Bihan et al. (2013) and Stahlmecke

et al. (2014a). They dropped the material under investigation from a defined height,

for example, 20-80 cm. Standard fast reading aerosol measurement tools such as an

FMPS, APS, or OPS were employed with these test methods to be able to determine

any release. Le Bihan et al. (2013) determined very small concentrations of about

10 #/cm³ in the clean box used in the test. Stahlmecke et al. (2014a) conducted the test

in a “normal” room simulating homeworker conditions (Figure 12.13). No significant

particle release could be determined in these conditions.

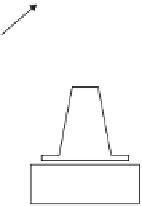

A third approach to test nano-objects release from nanomaterials is the one pur-

sued by Sachse et al. (2013b, Figure 12.14). They produced the so-called crash cones

of the nanomaterial of interest to be placed directly under a falling impactor with a

defined weight. The aerosol sampling lines were placed close to the crashing zone

in the test chamber. The SMPS measurements were conducted for extended peri-

ods prior and after the crash along with sampling with an electrostatical precipita-

tor. Significant release of nanoscale particles was observed for all materials, those

with silica nanofiller and without, but no significant differences in particle size and

number concentrations for the different materials were observed.

Three different approaches testing nano-object release from nanomaterials were

investigated, all of them simulating different conditions and hence release scenarios.

Direction of

impactor

DMA

CPC

Elastic

opening

ESP

Crash cone

Load cell

(a)

(b)

FIGURE 12.14

Experimental setup for testing of nano-objects release by mechanical shock

(a) and a crashed cone (b). (From Sachse, S. et al.,

NanoProduct Rev

. J., 1, 11, 2013a.)

Search WWH ::

Custom Search