Biomedical Engineering Reference

In-Depth Information

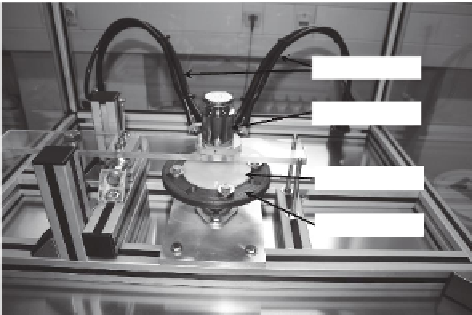

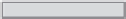

Within the nanoGEM project, IUTA developed an experimental setup to inves-

tigate possible nanoparticle release during sanding of various composite materials

using defined but adjustable test settings. Therefore, a test rig was constructed where

the electrical engine was placed outside of an isolated chamber, simultaneously

allowing particle measurements during the sanding procedure (Figure 12.5). The

chamber is flushed with HEPA filtered air through two inlets and sealed dustproof to

ensure low background particle concentrations. The test object is mounted to a rotat-

ing disk in the middle of the flow channel. The external motor moves the sanding

plate by means of a magnetic clutch. The rotational speed and thus the velocity of the

sample are adjustable. A stationary stamp fixes the sanding paper.

The sampling of the airborne sanding dust was conducted using conductive tubes.

The background measurement in the chamber served as reference for each exam-

ined material. Two different sandpapers (201 and 46.2 µm grit size) were used, the

Sampling lines

Weight

Sample

Rotating plate

(a)

FMPS

WELAS

(APS)

CPC

Weight

1 kg

Counter

weight

Extension holder

Stamp

Abrasive paper

Abrasion

test object

Abrasion plate

(Rotating disc)

(b)

FIGURE 12.5

Example of a test setup to investigate particle release by sanding. (Courtesy

of IUTA, nanoGEM.)

Search WWH ::

Custom Search