Biomedical Engineering Reference

In-Depth Information

rectangular sticks. After production the nanocomposite test samples that contained

2 mass% CNTs were broken apart manually and sanded with P220 sanding paper

(68 µm grit size) to remove excess material until final dimensions were achieved.

Other parameters with regard to the sanding process are not given. During the sand-

ing process airborne particle number concentrations were measured using a CPC and

an optical particle counter (OPC) at two locations (adjacent to the sanding process

and in the breathing zone of the operator). Cena and Peters (2011) used the ratios of

the geometric mean concentration measured during the sanding process to the mea-

sured background concentrations (P/B ratio) as indices of the impact of the process.

They found that during the sanding process the nanoparticle number concentration

was negligibly elevated compared to the background concentration with a P/B ratio

of 1.04. Furthermore, they found that sanding epoxy containing CNTs may generate

micrometer-sized particles with embedded CNTs as shown by the corresponding

P/B ratio of 5.90 and electron microscopy analyses.

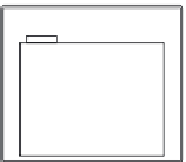

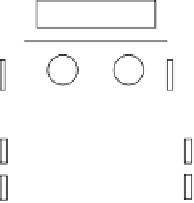

Huang et al. (2012) characterized the emission of the airborne particles from

epoxy resin test sticks with different CNT loadings and two commercial products

during a sanding process. An experimental setup consisting of a system to simulate

sanding and a system for sampling and monitoring airborne particles was developed

(Figure 12.4).

The experimental setup consisted of a sand blasting cabinet, which was housed

in a secondary clear plastic enclosure, both supplied with high efficiency particulate

airfilter (HEPA)-filtered air to maintain a low background concentration. A terminal

pump was used to extract a portion of the cabinet exhaust through a sampling mani-

fold from which the measurement devices, CPC, OPC, and scanning mobility particle

sizer (SMPS), received their sample flows. Inside the sand blasting cabinet a commer-

cial lathe was used where a disk plate with sanding paper was mounted to the spindle

Sanding simulation system

Sampling and monitoring system

Exhaust air

Plastic enclosure

Terminal

pump

Sampling

manifold

HEPA filter

Valve

Cabinet

with disc

sander

and lathe

Filter

CPC

SMPS

Sampling pump

HEPA filtered air mover

OPC

Pressure

gauge

#1

#2

Room air

R

oom air

AC volatege controller

FIGURE 12.4

Experimental setup used. (With kind permission from Springer

Science+Business Media:

J. Nanoparticle. Res

., Evaluation of airborne particle emissions

from commercial products containing carbon nanotubes, 14, 2012, 1-13, Huang, G. et al.)

Search WWH ::

Custom Search