Environmental Engineering Reference

In-Depth Information

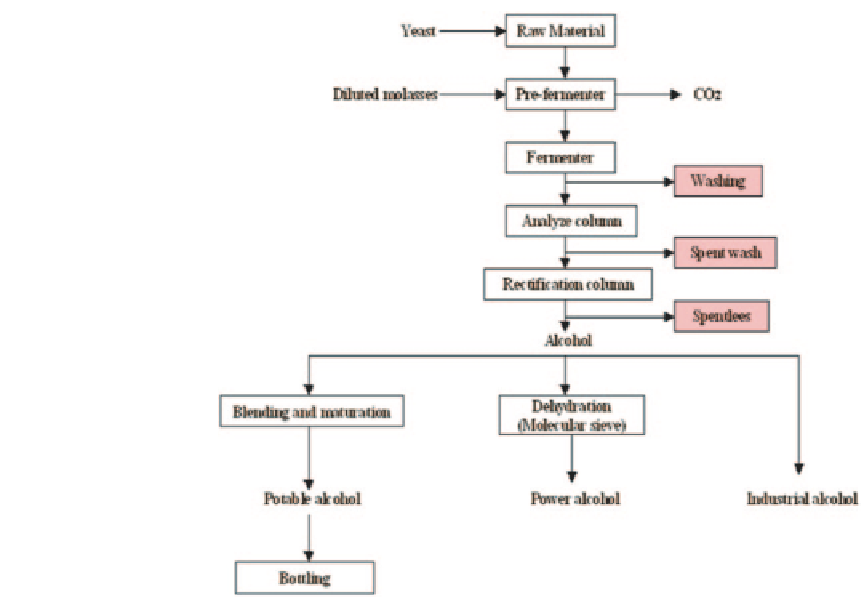

Fig. 2.1

Detailed process

of alcohol production

eries are an agro-based industry with around 300

units located mainly in rural, sugarcane-growing

regions. The total installed capacity is 3250 mil-

lion L alcohol per annum with an estimated

production of 2300.4 million L in 2006-2007

(Ethanol India

2007

). Bioethanol is produced

worldwide for beverage, industrial, chemical,

and some fuel use, by fermenting agricultural

products such as molasses, sucrose-containing

juices from sugarcane or sugarbeets, potatoes,

fruits, and grains (notably maize, wheat, grain

sorghum, barley, and rye). With growing popula-

tion, industrialization, and energy consumption,

coupled with an increasing reliance on fossil

fuels, the energy security needs of the world con-

tinue to escalate.

a.

Feed Preparation

Ethanol can be produced from a wide range

of feedstock. These include sugar-based (cane

and beet molasses, cane juice), starch-based

(corn, wheat, cassava, rice, barley), and cellu-

losic (crop residues, sugarcane bagasse, wood,

municipal solid wastes) materials. In gen-

eral, sugar-based feedstock containing read-

ily available fermentable sugars are preferred

while Indian distilleries almost exclusively

use sugarcane molasses The composition of

molasses varies with the variety of cane, the

agroclimatic conditions of the region, sugar

manufacturing process, and handling and stor-

age (Godbole

2002

).

b.

Fermentation

Yeast culture is prepared in the laboratory and

propagated in a series of fermenters. The feed

is inoculated with about 10 % by volume of

yeast (

Saccharomyces cerevisiae

) inoculum.

This is an anaerobic process carried out under

controlled conditions of temperature and pH

wherein reducing sugars are broken down to

ethyl alcohol and carbon dioxide. The reaction

is exothermic. To maintain the temperature be-

2.2

Critical Review

2.2.1

Process of Ethanol Production

Alcohol manufacture in distilleries consists of

four main steps, viz., feed preparation, fermenta-

tion, distillation, and packaging (Fig.

2.1

).

Search WWH ::

Custom Search